Karamin Diamita Graphite Electrodes Don Tanderun Arc na Lantarki A Masana'antar Karfe Da Kafa

Sigar Fasaha

Chart 1: Ma'aunin Fasaha Don Ƙananan Diamita Mai Zana Electrode

| Diamita | Sashe | Juriya | Ƙarfin Flexural | Matashi Modul | Yawan yawa | CTE | Ash | |

| Inci | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/ ℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

Jadawalin 2: Ƙarfin Ɗaukar Yanzu Don Ƙaramin Diamita Graphite Electrode

| Diamita | Load na Yanzu | Yawan Yanzu | Diamita | Load na Yanzu | Yawan Yanzu | ||

| Inci | mm | A | A/m2 | Inci | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Amfani

1.Anti-oxidation magani ga tsawon rai.

2.High-tsarki, high-yawa, karfi sinadaran kwanciyar hankali.

3.High machining daidaito, mai kyau surface karewa.

4.High inji ƙarfi, low lantarki juriya.

5. Resistant to fashe & spalling.

6.High juriya ga hadawan abu da iskar shaka da thermal girgiza.

Babban Aikace-aikacen

- Calcium carbide smelting

- Carborundum samar

- Corundum tacewa

- Rare karafa suna narkewa

- Ferrosilicon shuka refractory

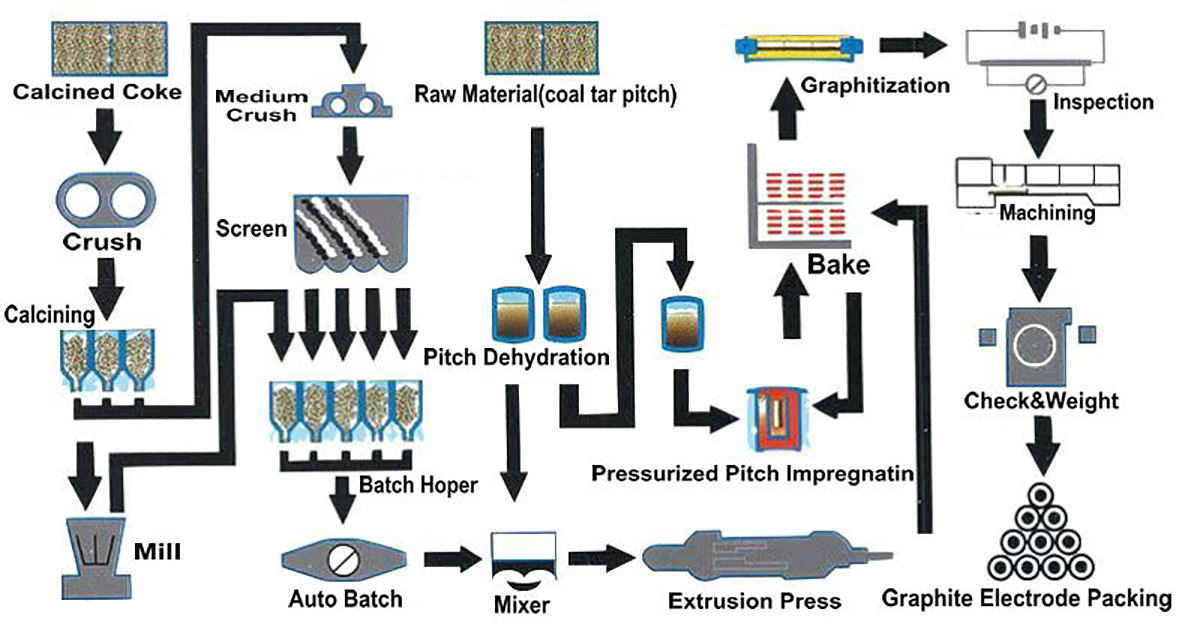

RP Graphite Electrode Production Process

Mai Sarrafa Ingantattun Tsarin Sama

1. Lalacewar ko ramukan kada su wuce sassa biyu akan saman lantarki na graphite, kuma ba a yarda da lahani ko girman ramuka su wuce bayanan da ke cikin tebur da aka ambata a ƙasa.

2.There is no transverse crack on the electrode surface.For longitudinal crack, da tsawon ya kamata ba fiye da 5% na graphite electrode kewaye, ta nisa ya zama a cikin 0.3-1.0mm range.Longitudinal crack data kasa 0.3mm data kamata. zama sakaci

3.The nisa ya m tabo (baki) yanki a kan graphite lantarki surface kamata ba kasa da 1/10 na graphite lantarki kewaye, da kuma tsawon m tabo (black) yanki a kan 1/3 na graphite lantarki tsawon. ba a yarda.