Karamin Diamita Furnace Graphite Electrode don murhun baka na lantarki don masana'antar karfe da masana'anta

Sigar Fasaha

Chart 1: Ma'aunin Fasaha Don Ƙananan Diamita Mai Zana Electrode

| Diamita | Sashe | Juriya | Ƙarfin Flexural | Matashi Modul | Yawan yawa | CTE | Ash | |

| Inci | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/ ℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

Jadawalin 2: Ƙarfin Ɗaukar Yanzu Don Ƙaramin Diamita Graphite Electrode

| Diamita | Load na Yanzu | Yawan Yanzu | Diamita | Load na Yanzu | Yawan Yanzu | ||

| Inci | mm | A | A/m2 | Inci | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Chart 3: Girman Electrode na Graphite & Haƙuri Don Ƙananan Diamita Mai Zane-zane

| Diamita na Suna | Ainihin Diamita (mm) | Tsawon Suna | Hakuri | |||

| Inci | mm | Max. | Min. | mm | Inci | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75-50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75-50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ± 100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ± 100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ± 100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ± 100 |

Babban Aikace-aikacen

- Calcium carbide smelting

- Carborundum samar

- Corundum tacewa

- Rare karafa suna narkewa

- Ferrosilicon shuka refractory

Hannun Umarni da Amfani Don Electrodes na Graphite

1. Cire murfin kariya na sabon rami na lantarki, duba ko zaren da ke cikin rami na lantarki ya cika kuma zaren bai cika ba, tuntuɓi ƙwararrun injiniyoyi don sanin ko za a iya amfani da lantarki;

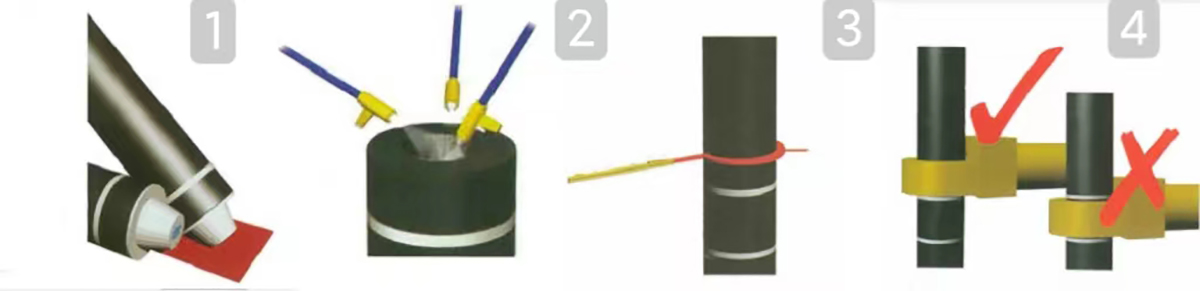

2. Maƙala rataye na lantarki a cikin rami na lantarki a gefe ɗaya, kuma sanya matashin mai laushi a ƙarƙashin ɗayan ƙarshen lantarki don guje wa lalata haɗin lantarki; (duba pic1)

3.Yi amfani da iskar da aka matse don busa kura da yadudduka a saman da ramin haɗin lantarki, sannan a tsaftace saman da mahaɗin sabon lantarki, tsaftace shi da goga;(duba pic2)

4.Daga sabon na'urar lantarki sama da wutar lantarki mai jiran aiki don daidaitawa tare da ramin lantarki kuma fada a hankali;

5.Yi amfani da madaidaicin ƙimar juzu'i don kulle lantarki da kyau; (duba pic3)

6.Ya kamata a sanya abin riƙewa daga layin ƙararrawa.(duba pic4)

7.A cikin lokacin tsaftacewa, yana da sauƙi don sanya electrode na bakin ciki da kuma haifar da raguwa, haɗin gwiwa ya fadi, ƙara yawan amfani da lantarki, don Allah kar a yi amfani da na'urori don tayar da abun ciki na carbon.

8.Due da daban-daban albarkatun kasa amfani da kowane manufacturer da kuma masana'antu tsari, da jiki da kuma sinadaran Properties na lantarki da kuma gidajen abinci na kowane manufacturer. Don haka ana amfani da shi, a ƙarƙashin yanayi na gaba ɗaya, Don Allah kar a haɗa na'urorin lantarki da haɗin gwiwa waɗanda masana'antun daban-daban ke samarwa.