Babban Maɗaukaki Ƙaramin Diamita Tanderu Graphite Electrode Ga Ladle Furnace Blast Furnace A cikin Waƙar Karfe

Sigar Fasaha

Chart 1: Ma'aunin Fasaha Don Ƙananan Diamita Mai Zana Electrode

| Diamita | Sashe | Juriya | Ƙarfin Flexural | Matashi Modul | Yawan yawa | CTE | Ash | |

| Inci | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/ ℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

Jadawalin 2: Ƙarfin Ɗaukar Yanzu Don Ƙaramin Diamita Graphite Electrode

| Diamita | Load na Yanzu | Yawan Yanzu | Diamita | Load na Yanzu | Yawan Yanzu | ||

| Inci | mm | A | A/m2 | Inci | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Chart 3: Girman Electrode na Graphite & Haƙuri Don Ƙananan Diamita Mai Zane-zane

| Diamita na Suna | Ainihin Diamita (mm) | Tsawon Suna | Hakuri | |||

| Inci | mm | Max. | Min. | mm | Inci | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75-50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75-50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ± 100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ± 100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ± 100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ± 100 |

Babban Aikace-aikacen

- Calcium carbide smelting

- Carborundum samar

- Corundum tacewa

- Rare karafa suna narkewa

- Ferrosilicon shuka refractory

Hannun Umarni da Amfani Don Electrodes na Graphite

1.Yi amfani da kayan aikin ɗagawa na musamman don rayuwa da lantarki na graphite don guje wa lalacewa yayin sufuri.(duba hoto1)

2.Wajibi ne a nisantar da na'urar lantarki daga ruwa ko jika, dusar ƙanƙara, a bushe.(duba hoto2)

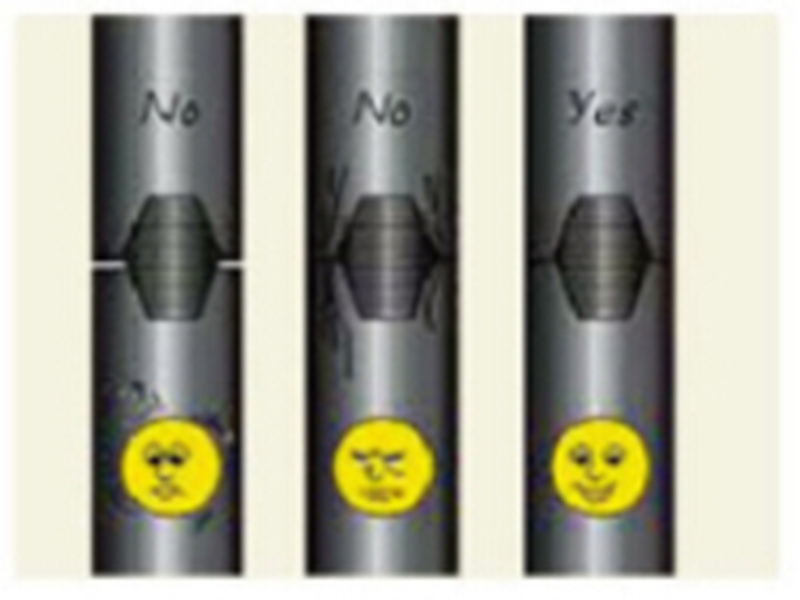

3.Bincika a hankali kafin amfani, tabbatar da soket da zaren nono sun dace don amfani, gami da duba farar, toshe.(duba pic3)

4. Tsaftace bakin nono da zaren kwasfa da iska mai matsewa.(duba pic4)

5.Kafin amfani, da graphite lantarki dole ne a bushe a cikin tanderun, da bushewa zafin jiki ya zama kasa da 150 ℃, da bushe lokaci ya zama fiye da 30hours.(duba pic5)

6.Graphite lantarki dole ne a haɗa tam kuma kai tsaye tare da dacewa jujjuya karfin juyi.(duba pic6)

7.To kauce wa graphite lantarki breakage, sanya babban part a cikin ƙananan matsayi da karamin sashi a cikin babba matsayi.