Graphite Electrode Yana Amfani Don Corundum Refining Electric Arc Furnace Small Diamita Furnace Electrodes

Sigar Fasaha

Chart 1: Ma'aunin Fasaha Don Ƙananan Diamita Mai Zana Electrode

| Diamita | Sashe | Juriya | Ƙarfin Flexural | Matashi Modul | Yawan yawa | CTE | Ash | |

| Inci | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/ ℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nono | 5.8-6.5 | ≥16.0 | ≤13.0 | 1.74 | ≤2.0 | ≤0.3 | ||

Jadawalin 2: Ƙarfin Ɗaukar Yanzu Don Ƙaramin Diamita Graphite Electrode

| Diamita | Load na Yanzu | Yawan Yanzu | Diamita | Load na Yanzu | Yawan Yanzu | ||

| Inci | mm | A | A/m2 | Inci | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Chart 3: Girman Electrode na Graphite & Haƙuri Don Ƙananan Diamita Mai Zane-zane

| Diamita na Suna | Ainihin Diamita (mm) | Tsawon Suna | Hakuri | |||

| Inci | mm | Max. | Min. | mm | Inci | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75-50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75-50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ± 100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ± 100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ± 100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ± 100 |

Babban Aikace-aikacen

- Calcium carbide smelting

- Carborundum samar

- Corundum tacewa

- Rare karafa suna narkewa

- Ferrosilicon shuka refractory

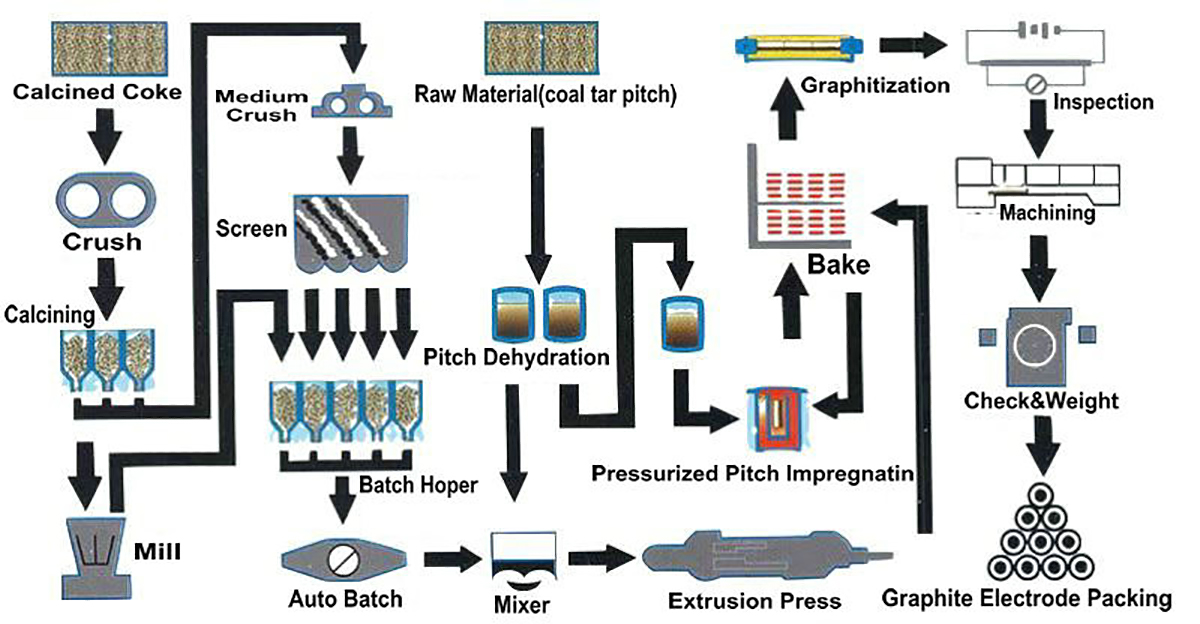

RP Graphite Electrode Production Process

Amfanin Gufan

1. Anyi daga kayan aikin graphite masu inganci, ƙananan ƙananan na'urorin lantarki na graphite an gina su don tsayayya da matsanancin yanayin zafi da kuma samar da kyakkyawan yanayin lantarki. Wannan yana tabbatar da ingantaccen tsari na narkewa, yana haifar da ingantaccen ingancin samfur da rage yawan kuzari.

2. Ƙananan ƙananan waɗannan na'urorin lantarki suna ba da izini don ƙarin iko mai mahimmanci akan tsarin narkewa, yin su cikakke don aikace-aikacen da ke buƙatar babban daidaito da sakamako mai kyau. Ko kuna samar da allura ko gyaran karafa, na'urorin mu zasu taimaka muku cimma sakamakon da ake so tare da daidaitattun daidaito.

3. Ƙananan ƙananan ginshiƙan graphite na lantarki sun dace da nau'o'in masana'antu, ciki har da masana'antun karfe, sarrafa sinadarai, da simintin ƙarfe. Komai girman aikin ku, ana iya keɓance na'urorin mu don biyan takamaiman buƙatun ku.

4. A cikin masana'antar ƙarfe, ana amfani da ƙananan na'urorin lantarki na graphite a cikin wutar lantarki, inda suke taka muhimmiyar rawa wajen samar da ƙarfe mai inganci. Ƙananan girman su yana ba da izini ga madaidaicin iko akan tsarin narkewa, tabbatar da daidaiton sakamako da rage yawan sharar gida.

5. A cikin sarrafa sinadarai, wayoyinmu suna da mahimmanci don samar da sinadarin calcium carbide da kuma tace carborundum. Waɗannan matakan suna buƙatar madaidaicin sarrafa zafin jiki, waɗanda na'urorin mu na lantarki suke isar da su da cikakken daidaito.

6. Domin karfe simintin gyaran kafa, mu kananan diamita graphite lantarki amfani da smelting na rare karafa da Ferrosilicon shuke-shuke. A m conductivity na graphite damar domin ingantaccen narkewa na karafa, sakamakon da sauri samar hawan keke da mafi girma overall yawan aiki.