Graphite Electrodes Nonuwa 3tpi 4tpi Haɗa Pin T3l T4l

Bayani

Kan nono mai graphite ƙarami ne amma muhimmin sashi na aikin ƙera ƙarfe na EAF. Abu ne mai siffar Silindrical wanda ke haɗa wutar lantarki zuwa tanderun. Yayin aikin ƙera ƙarfe, ana saukar da wutar lantarki a cikin tanderun kuma sanya shi cikin hulɗa da narkakken ƙarfe. Lantarki na gudana ta hanyar lantarki, yana haifar da zafi, wanda ke narkar da karfe a cikin tanderun. Nono yana taka muhimmiyar rawa wajen kiyaye ingantaccen haɗin lantarki tsakanin lantarki da tanderun wuta.

Sigar Fasaha

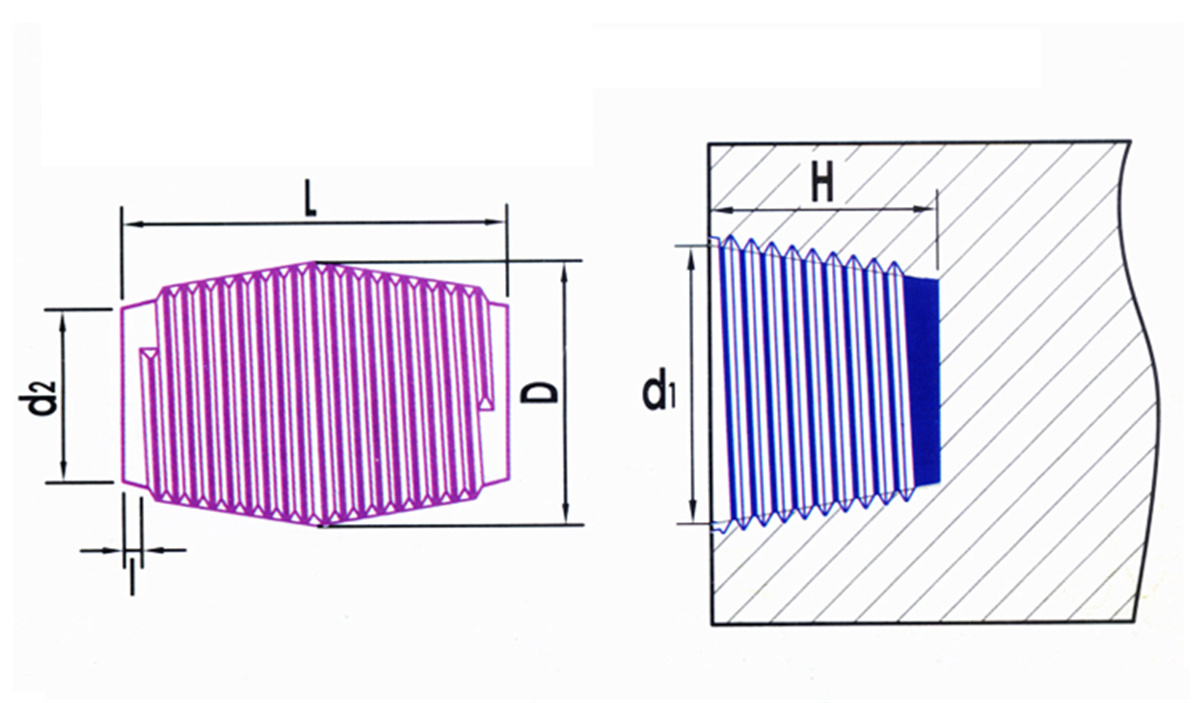

Gufan Carbon Conical Nono da Zane Socket

| Diamita na Suna | Lambar IEC | Girman Nonon (mm) | Girman Socket(mm) | Fita | |||||

| mm | inci | D | L | d2 | I | d1 | H | mm | |

| Hakuri (-0.5~0) | Haƙuri (-1~0) | Haƙuri (-5~0) | Haƙuri (0~0.5) | Haƙuri (0~7) | |||||

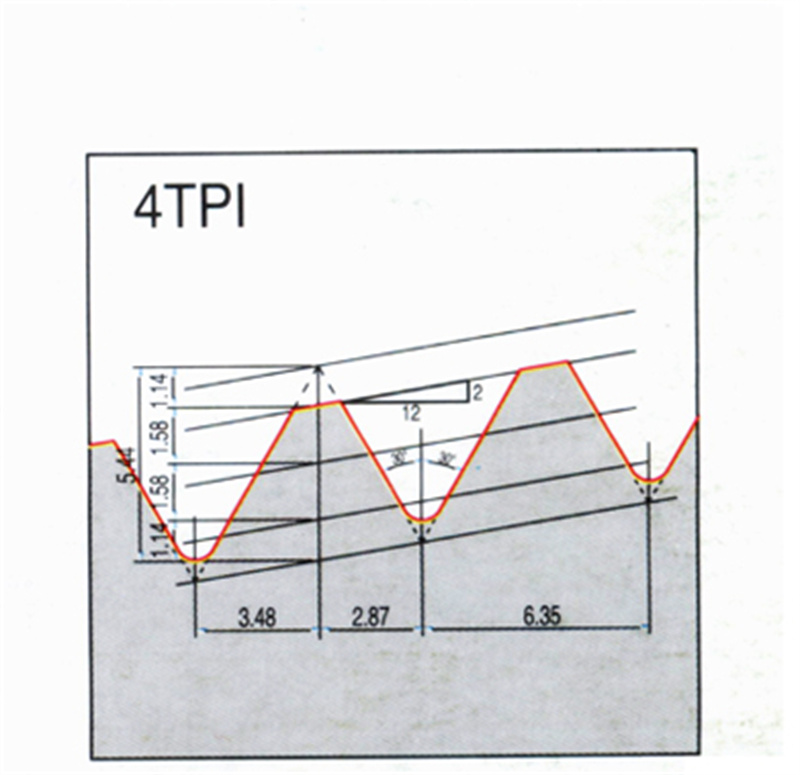

| 200 | 8 | 122T4N | 122.24 | 177.80 | 80.00 | <7 | 115.92 | 94.90 | 6.35 |

| 250 | 10 | 152T4N | 152.40 | 190.50 | 108.00 | 146.08 | 101.30 | ||

| 300 | 12 | 177T4N | 177.80 | 215.90 | 129.20 | 171.48 | 114.00 | ||

| 350 | 14 | 203T4N | 203.20 | 254.00 | 148.20 | 196.88 | 133.00 | ||

| 400 | 16 | 222T4N | 222.25 | 304.80 | 158.80 | 215.93 | 158.40 | ||

| 400 | 16 | 222T4L | 222.25 | 355.60 | 150.00 | 215.93 | 183.80 | ||

| 450 | 18 | 241T4N | 241.30 | 304.80 | 177.90 | 234.98 | 158.40 | ||

| 450 | 18 | 241T4L | 241.30 | 355.60 | 169.42 | 234.98 | 183.80 | ||

| 500 | 20 | 269T4N | 269.88 | 355.60 | 198.00 | 263.56 | 183.80 | ||

| 500 | 20 | 269T4L | 269.88 | 457.20 | 181.08 | 263.56 | 234.60 | ||

| 550 | 22 | 298T4N | 298.45 | 355.60 | 226.58 | 292.13 | 183.80 | ||

| 550 | 22 | 298T4L | 298.45 | 457.20 | 209.65 | 292.13 | 234.60 | ||

| 600 | 24 | 317T4N | 317.50 | 355.60 | 245.63 | 311.18 | 183.80 | ||

| 600 | 24 | 317T4L | 317.50 | 457.20 | 228.70 | 311.18 | 234.60 | ||

| 650 | 26 | 355T4N | 355.60 | 457.20 | 266.79 | 349.28 | 234.60 | ||

| 650 | 26 | 355T4L | 355.60 | 558.80 | 249.66 | 349.28 | 285.40 | ||

| 700 | 28 | 374T4N | 374.65 | 457.20 | 285.84 | 368.33 | 234.60 | ||

| 700 | 28 | 374T4L | 374.65 | 558.80 | 268.91 | 368.33 | 285.40 | ||

| Diamita na Suna | Lambar IEC | Girman Nonon (mm) | Girman Socket(mm) | Fita | |||||

| mm | inci | D | L | d2 | I | d1 | H | mm | |

| Hakuri (-0.5~0) | Haƙuri (-1~0) | Haƙuri (-5~0) | Haƙuri (0~0.5) | Haƙuri (0~7) | |||||

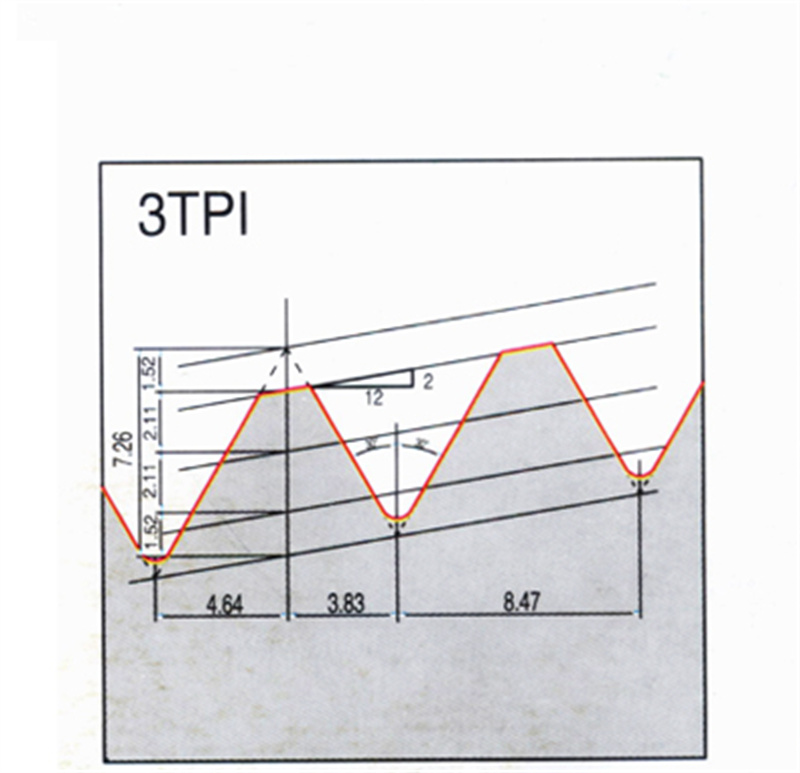

| 250 | 10 | 155T3N | 155.57 | 220.00 | 103.80 | <7 | 147.14 | 116.00 | 8.47 |

| 300 | 12 | 177T3N | 177.16 | 270.90 | 116.90 | 168.73 | 141.50 | ||

| 350 | 14 | 215T3N | 215.90 | 304.80 | 150.00 | 207.47 | 158.40 | ||

| 400 | 16 | 241T3N | 241.30 | 338.70 | 169.80 | 232.87 | 175.30 | ||

| 450 | 18 | 273T3N | 273.05 | 355.60 | 198.70 | 264.62 | 183.80 | ||

| 500 | 20 | 298T3N | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | ||

| 550 | 22 | 298T3N | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | ||

| Electrode | Daidaitaccen Nauyin Nonuwa | ||||||||

| Girman Electrode na Suna | 3TPI | 4TPI | |||||||

| Diamita × Tsawon | T3N | T3L | T4N | T4L | |||||

| inci | mm | lbs | kg | lbs | kg | lbs | kg | lbs | kg |

| 14 × 72 | 350 × 1800 | 32 | 14.5 | - | - | 24.3 | 11 | - | - |

| 16 × 72 | 400 × 1800 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 16 × 96 | 400 × 2400 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 18 × 72 | 450 × 1800 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 18 × 96 | 450 × 2400 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 20 × 72 | 500 × 1800 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 84 | 500 × 2100 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 96 | 500 × 2400 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 110 | 500 × 2700 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 22 × 84 | 550 × 2100 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 22 × 96 | 550 × 2400 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 24 × 84 | 600 × 2100 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 96 | 600 × 2400 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 110 | 600 × 2700 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| Diamita Electrode | inci | 8 | 9 | 10 | 12 | 14 |

| mm | 200 | 225 | 250 | 300 | 350 | |

| Lokacin Sauƙaƙe | N·m | 200-260 | 300-340 | 400-450 | 550-650 | 800-950 |

| Diamita Electrode | inci | 16 | 18 | 20 | 22 | 24 |

| mm | 400 | 450 | 500 | 550 | 600 | |

| Lokacin Sauƙaƙe | N·m | 900-1100 | 1100-1400 | 1500-2000 | 1900-2500 | 2400-3000 |

Umarnin shigarwa

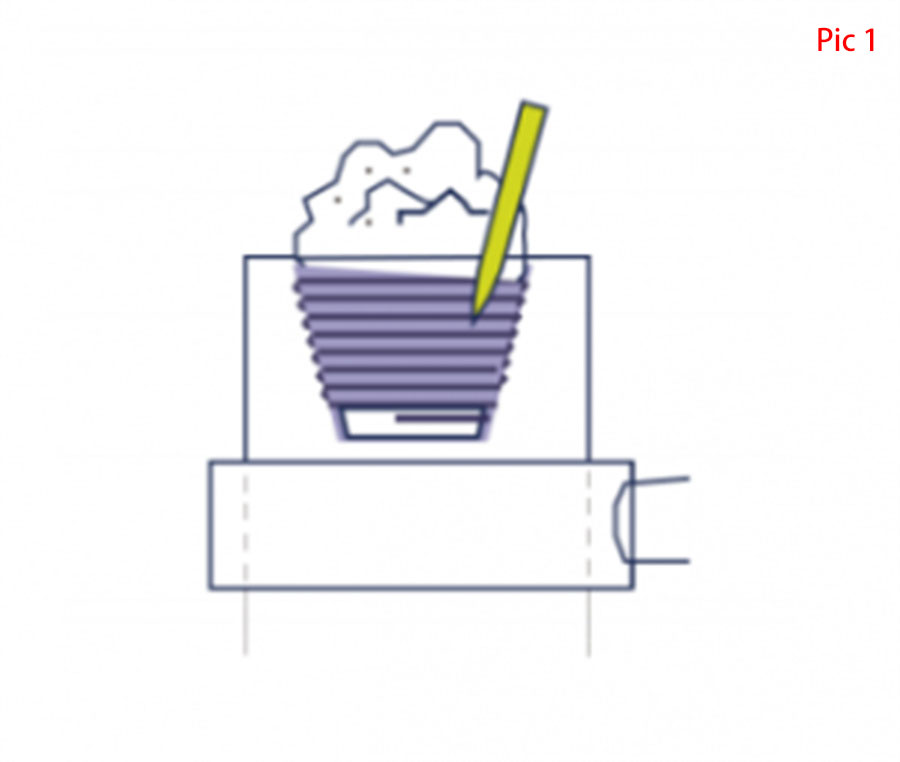

- Kafin shigar da graphite electrode nono,Tsaftace kura da datti a saman da soket na lantarki da nono tare da matsawa iska; (duba hoto 1)

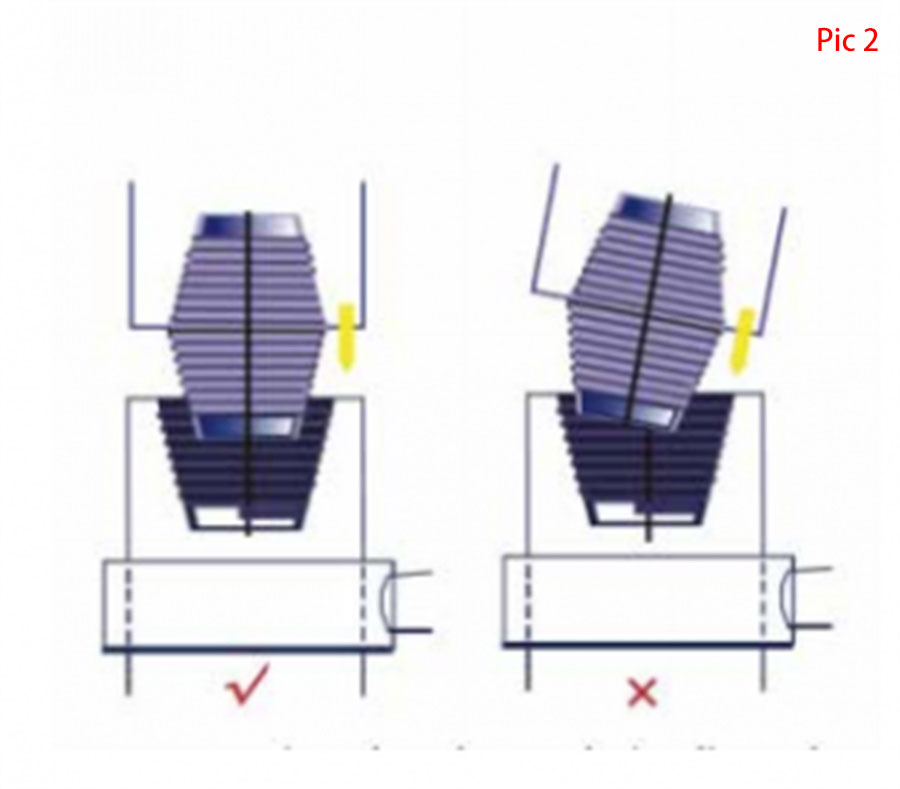

- Tsakanin layin graphite electrode nono yakamata a kiyaye daidai gwargwado yayin haɗin lantarki guda biyu na graphite tare; (duba hoto 2)

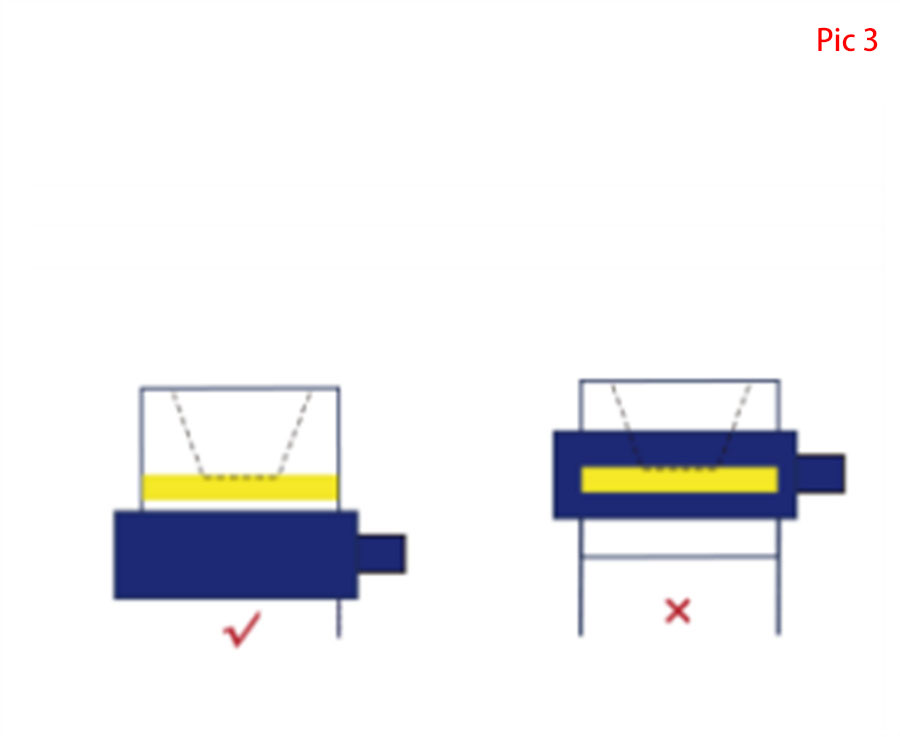

- Electrode clamper dole ne a riƙe shi a daidai matsayi: a waje da layin aminci na ƙarshen mafi girma; (duba hoto 3)

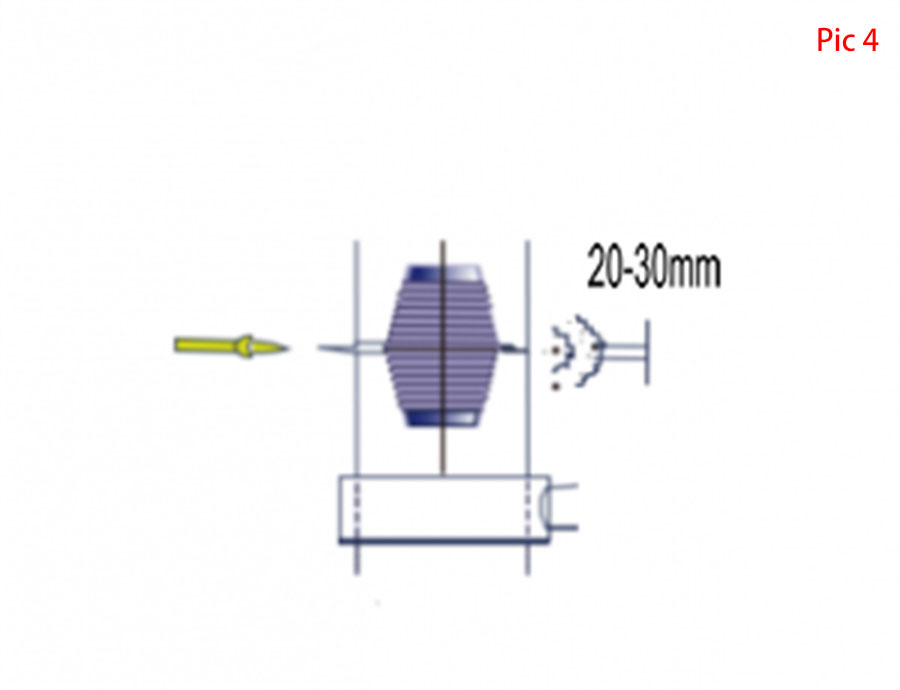

- Kafin a danne nono, tabbatar da tsaftar saman nonon ba tare da kura ko datti ba. (duba hoto 4)

Nonuwar graphite lantarki abu ne mai mahimmanci a cikin tsarin ƙera ƙarfe na EAF. Ingancin sa kai tsaye yana shafar inganci da amincin tsarin. Yin amfani da nonuwa masu inganci yana da mahimmanci don hana haɗarin lantarki da kuma tabbatar da tsari mai santsi da inganci. A cewar bayanan masana'antu, sama da kashi 80% na haɗarin lantarki suna haifar da karyewar nonuwa da faɗuwa. Domin zabar nonon da ya dace, dole ne a yi la'akari da abubuwan da ke ƙasa.

- Ƙarfafawar thermal

- Lantarki resistivity

- Yawan yawa

- Ƙarfin injina

Lokacin zabar graphite electrode nono, yana da mahimmanci a yi la'akari da ingancinsa, girmansa, da siffarsa, da dacewarsa tare da ƙayyadaddun lantarki da tanderu. Ta hanyar zabar nonon da ya dace, masana'antun za su iya inganta ingancin karfe kuma su rage farashin da ke hade da raguwa da rashin aiki.

Ciki har da ma'aunin zafinsa, tsayayyar wutar lantarki, yawa, da ƙarfin injina.